Breakaway couplings are safety devices that protect equipment and personnel from the consequences of a sudden break in the transfer of fluids. They are designed to disconnect when a predetermined load or tension is reached, such as when a vessel unexpectedly moves away from its mooring, a hose ruptures, or there is an abrupt change in pressure. In the market, there are two main types of breakaway couplings – marine and industrial. In this blog, we will discuss the difference between marine and industrial breakaway couplings.

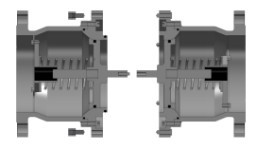

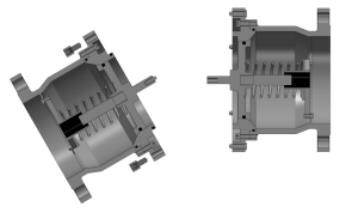

Marine breakaway couplings are specifically designed for use in the offshore and marine environment. They are typically larger and more robust than industrial breakaway couplings, and are designed to withstand the harsh conditions of the open sea. Marine breakaway couplings are commonly used on hoses that transfer crude oil, liquefied natural gas (LNG), and other hazardous chemicals between ships, offshore platforms, and onshore facilities.

Marine breakaway couplings work by separating the hose into two parts when a predetermined load or tension is reached. They are designed to ensure that no liquid is spilled, and that the hose is safely and automatically disconnected from the pipeline. Marine breakaway couplings can be manually or automatically reset, depending on the specific application and requirements.

Industrial breakaway couplings, on the other hand, are used in a variety of applications, such as the transfer of chemicals, oil, gas, and other hazardous fluids in industrial settings. Industrial breakaway couplings are typically smaller than their marine counterparts, and are designed to be installed at the end of a hose, pipe or loading arm. They are designed to protect equipment and personnel from the consequences of a sudden hose or pipe breakage.

Industrial breakaway couplings work in a similar way to marine breakaway couplings, by separating the hose or pipe into two parts when a predetermined load or tension is reached. They are designed to prevent spills and protect equipment and personnel in the event of a sudden hose or pipe breakage. Industrial breakaway couplings can also be manually or automatically reset.

In conclusion, the main difference between marine and industrial breakaway couplings is their application. While both types of couplings are designed to protect equipment and personnel from the consequences of a sudden break in fluid transfer, marine breakaway couplings are specifically designed for use in the offshore and marine environment, while industrial breakaway couplings are used in a variety of industrial settings. Both types of couplings play an important role in ensuring the safety of personnel and equipment, and their selection should be based on the specific application and requirements.