BreakAways provide safety solutions to suit Loading Arms and Hoses when subjected to unwarranted load caused by drive away and pull incidents.

BreakAway’s act as the weakest link in the transfer system. Hence before the hose gets ruptured or the loading arms break these couplings are engineered to Break at a predefined force, stopping the flow of the service media. This eliminates the risk of spillages or any other major accidents.

How It Works

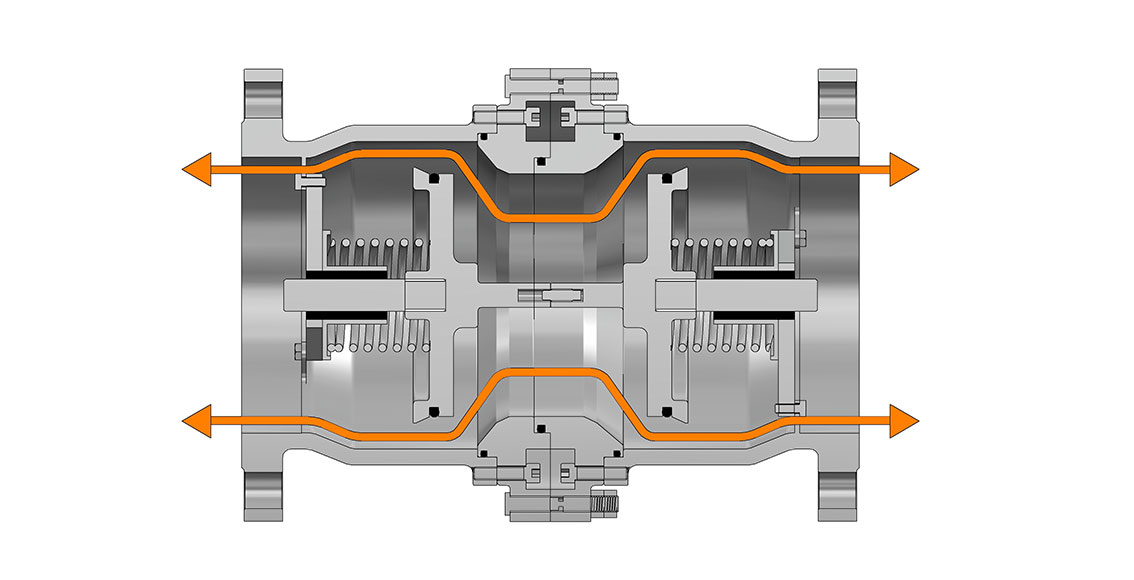

Under normal circumstances the BreakAway is in Flow position and the liquid or gas can transfer smoothly. The male and female couplings are sealed from the pistons ensuring no leakages.

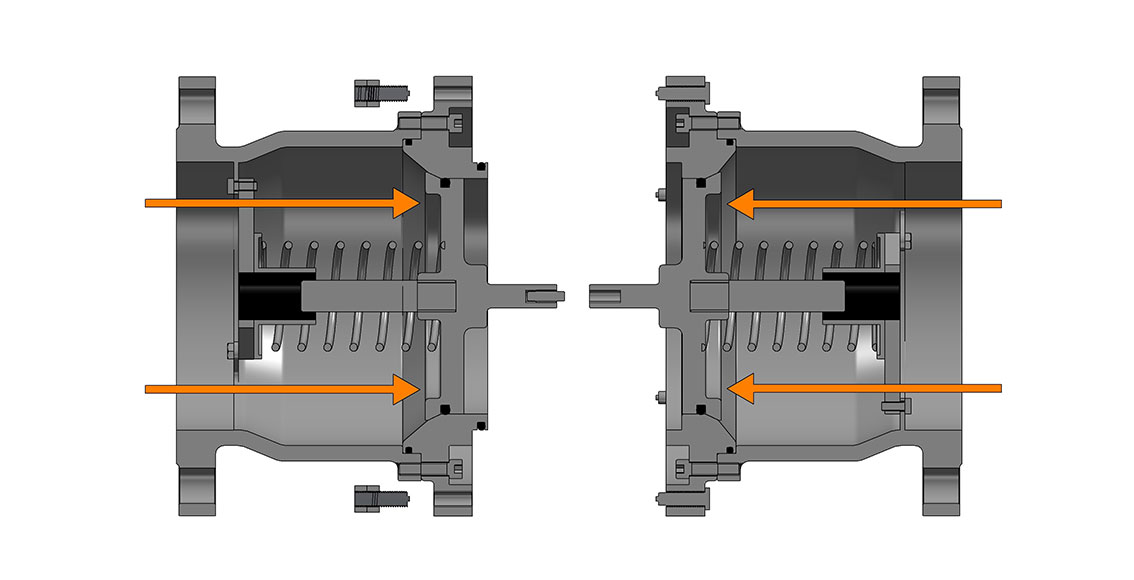

When there is a sudden excessive load on the couplings due to a pull or a drive away incident the break pins break. These break pins are designed to break at a pre calculated load.

Once the break pins break the coupling male and female isolate, instantaneously the valves (pistons) on the couplings close due to the spring. This leads to stoppage of the flow path for the media with minimal spillage.

DRIPLEX BreakAways can be easily reset with a new set of break pins and o-rings need to be changed.

BreakAways come in two variants.

Industrial BreakAways

Installed in between a fixed connection like a Manifold or similar and a hose and loading arm. This variant breaks at any angle between 90 Deg to 180 Deg.

Marine BreakAways

These couplings are usually installed between two hose strings. Marine BreakAways are designed to break only when axial load is applied. The DRIPLEX BreakAway is a high-performance safety product, provide the best flow rate, easily handled, lightweight and smaller design.